Ramie, also known as China grass, comes from China’s native bast fiber. It is a fiber-yielding plant that belongs to the nettle family. It has a similar look to European nettle but without the prickles. The green ramie, or rhea, is also a source of fiber that is speculated to be originated from Malaysia.

The textile industry got a new addition of fabric from fine-class Ramie fiber a long time back. The fabric has been gathering popularity in the textile market as it is an alternative to synthetic fabric. In this article, we will dive further into what ramie fabric is and other information to know about it.

Table Of Contents

What is Ramie Fabric, exactly?

Ramie is a natural woven fabric made from the bast fiber of the ramie plant. It's also known as China linen, grass linen, or grass cloth. It is a fiber similar to jute, flax, and hemp. Ramie occurs from the stalks of plants and flowers and is considered a vegan silk alternative that is lightweight and airier, making the fiber eco-friendly and incredibly sustainable. It is sometimes mistaken to be linen, but the fiber looks like silk and feels lustrous. People know of this fabric for being able to hold its shape and not wrinkle much. Often, ramie is blended with silk, cotton, or other synthetic materials as it is not very durable.

What is Ramie Fabric Made of?

Ramie consists of cellulose fiber and is produced from the stalks of a Chinese cultivated plant named Chinese Nettle or Boehmeria Nivea. It has other names such as rhea, China grass, or grass cloth. The extraction process of this fiber is complicated, and the fabric is premium and often expensive. There are 2 types of Ramie fiber: white ramie from Boehmeria nivea and green ramie from utilis plants. Both plants grow mainly in Malaysia and China, and these regions used Ramie fiber in the past to make clothes.

Everyone loves an eco-friendly material for their clothes, which is one of the specialties of ramie. Within a year, ramie is usually harvested 2 to 3 times. Still, if the growing conditions are suitable, it can be extracted up to 6 times. While harvesting this fiber, nothing goes to waste from the raw material. The fiber gets extracted from the plant’s bark, and its cellulose is used in making fine paper. Also, the leaves are edible for animals. All of these make ramie an environmentally sustainable fabric.

Manufacturing Process of Ramie Fabric

At first, ramie is harvested as soon as the plants form flowers, which means that the plant will not grow anymore and will produce maximum fiber.

⬇ï¸

The stems are harvested by cutting right above the lateral root or bending the stem, and the cortex is stripped from the stem.

⬇ï¸

While the plants are fresh, the stems should be decorticated. Otherwise, the bark will be tough to remove as the plants dry out.

⬇ï¸

A machine does the decortication process to remove the cortex or bark. It is essential to prevent bacteria and fungi from investing in it.

⬇ï¸

The bark ribbon has to be dried out soon enough.

⬇ï¸

Then, the cortex needed to be scraped off to eliminate most of the outer bark, known as parenchyma. This also helps remove many gums and pectin from the stalk.

⬇ï¸

The remaining cortex material is then cleaned and dried, and the spinnable fiber is extracted by degumming it.

⬇ï¸

Later, ramie needed to be mixed with natural fibers to make it more durable. It will make the fabric similar to a coarse canvas or fine linen.

2 Types of Ramie Fabric:

Ramie exists in two kinds, but both types produce fiber that has a pure white color. They are:

1. White ramie -

Also known as Chinese plant, true ramie, or China grass, these are the most p. These plants have heart-shaped leaves; their undersides are white and have dense, little hairs, giving them a shiny, silvery look. With the stinging nettles, the difference is that the fuzziness does not sting.

2. Green ramie –

Also known as a rhea, it is another type of ramie which is believed to be initiated from the Malay Peninsula. The plants are more suitable to grow in tropical regions. They have relatively more minor leaves, and the underside is green.

Properties of Ramie Fabric:

|

Fabric Name |

Ramie fabric |

|

Manufacturing Materials |

Comes from the Ramie plant, also known as Boehmeria nivea. |

|

Fabric Durability |

Not good; it needs to be blended with other materials to make it durable. |

|

Fabric Breathability |

Breathes well, making it good for summer. |

|

Stretch Ability |

Not good, ramie is brittle and stiff, so it will break. |

|

Fabric Shine |

Ramie is a fine fabric which gives it a shiny and whitish appearance. |

|

Fabric drape Ability |

Moderate drape ability |

|

Heat Retention Ability |

Low to moderate |

|

Prone to Bubbling |

Low |

|

Water resistant Ability |

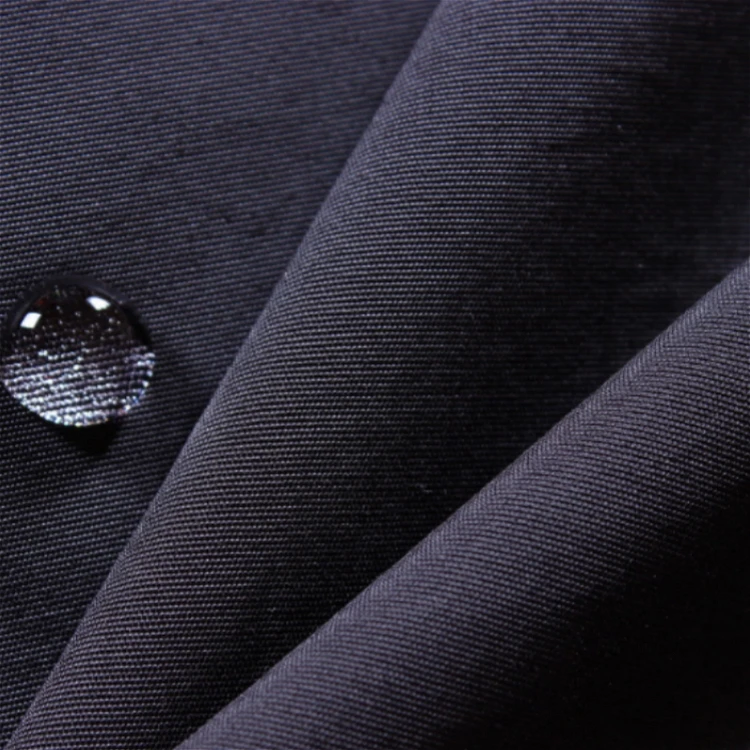

Extremely absorbent and gets more potent when it is drenched. |

|

Washing temperatures |

It should be washed at 40°C in the washing machine |

|

Cost of production |

High as the extraction of ramie is expensive. |

|

Fabric quality |

Premium quality with a silky and luster appearance. |

|

Resemblance |

Looks like silk as it gives a shiny glaze. |

|

Fabric Stain |

It is naturally resistant to stain and easy to wash. |

|

Fiber density |

Ranges from 1.50 to 1.55 |

Ramie Fabric Properties

Characteristics of Ramie fabric.

Ramie fabric has some fantastic features that will set it apart from other fabrics. It offers impressive breathability and can is easy to drape as well. Let us take a look at some of the features of this fabric.

Good breathability

Ramie has fantastic breathability, and in this case, it resembles a lot with linen and cotton. It keeps you cool during the warm weather as the fabric lets a lot of air pass through it.

Strongest natural fibers

Ramie has been used to manufacture clothes for a long time as the fibers are one of the most potent natural fibers. As the fibers are held tightly together, ramie can be brittle.

Very comfortable

Even though this fabric is said to be linen, it does not feel itchy. Over time, the fabric might get rougher, but it still does not feel prickly against the skin. If your skin is sensitive, then you might react differently to ramie.

Does not shrink

One of the unique qualities of ramie is that it does not shrink or form wrinkles. Even if you wash the fabric in hot water, ramie can hold its shape well. Ramie-made clothing will retain its initial shape for a long time.

Rot-resistant

Ramie is naturally resistant to bacteria, fungi, rot, mildew, and other pesticides, making it easy to care for. Also, insects or moths will not attack quickly to ramie as the fiber is unaffected by light.

Easy to care for

Ramie is easy to care for as its strength increases when wet. Another thing is ramie does not lose its shape or shrink during washes. With repeated washing, the fabric becomes more lustrous and smoother.

Ramie Fabric Advantages and Disadvantages

The ramie fabric advantages and disadvantages are as follows:

Advantages of Ramie Fabric

- Durable and strong.

- High tensile strength that is 8x of cotton and 7x of silk.

- Anti-resistant to bacteria, mildew, and insect attacks.

- Extremely absorbent.

- Highly comfortable to wear.

- Natural resistance to stains.

- Strength increases when it is wet.

- Withstand high temperatures during washing.

- Smooth and lustrous appearance that improves with laundering.

Disadvantages of Ramie Fabric

- Wrinkles easily.

- Lower elasticity.

- Low abrasion resistance.

- Stiff and brittle.

Applications of Ramie

- Used for shirts and shorts.

- Children’s clothes.

- Suits and pants.

- Handkerchiefs.

- Upholstery fabrics.

- Dish towels.

- Straw hats.

- Woven fire hoses.

- Filter clothes.

- Packaging materials.

- Narrow weaving.

- Industrial sewing thread.

Common FAQs on What is Ramie?

Why is Ramie Expensive?

The extraction process of ramie from the plant’s bark to woven textile is very long and expensive. It is not ideal to use chemicals as they will hurt the plant. So naturally, products consisting of ramie are also costly.

How long does it take for ramie plants to grow?

A ramie plant lasts up to 6 to 20 years. It can be harvested almost six times a year if the environmental conditions suit the plant.

Does ramie fabric have good elasticity?

The ramie fibers are very brittle and stiff; for this reason, ramie alone does not have good elasticity. It has high tensile strength, but it has very low flexibility. The fabric also lacks resiliency.

Is the ramie extraction process long?

Ramie fiber takes a long time to extract. The first harvesting is done after 17 days of the plantation. The subsequent succeeding harvests will carry out after 45 to 60 days.

Final Words:

Ramie is a fiber that has been around for a long time and is most popular around the east side of the world. The fiber comes from plants, and it has many advantages. It is resistant to chemicals and insects. This fiber is strong, and its strength increases when it is wet. The fabric made from this fiber is expensive, premium quality, and used in many home items. Ramie is also eco-friendly, so it is a sustainable fabric. This article has listed all the information on what is ramie fabric.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.