Bonded fabric, being a material, consists of fibers adhesively forming a sheet. There is a necessary property of the Bonded fabric, for instance- Heat Resistant Qualities. It is understandable that the bonded fabric gradually transfers heat. Yet, the bonded fabric is applicable to create the desired shape pattern. This article will take you into understanding different properties and advantage areas of Bonded fabric concisely.

Table Of Contents

What is Bonded Fabric?

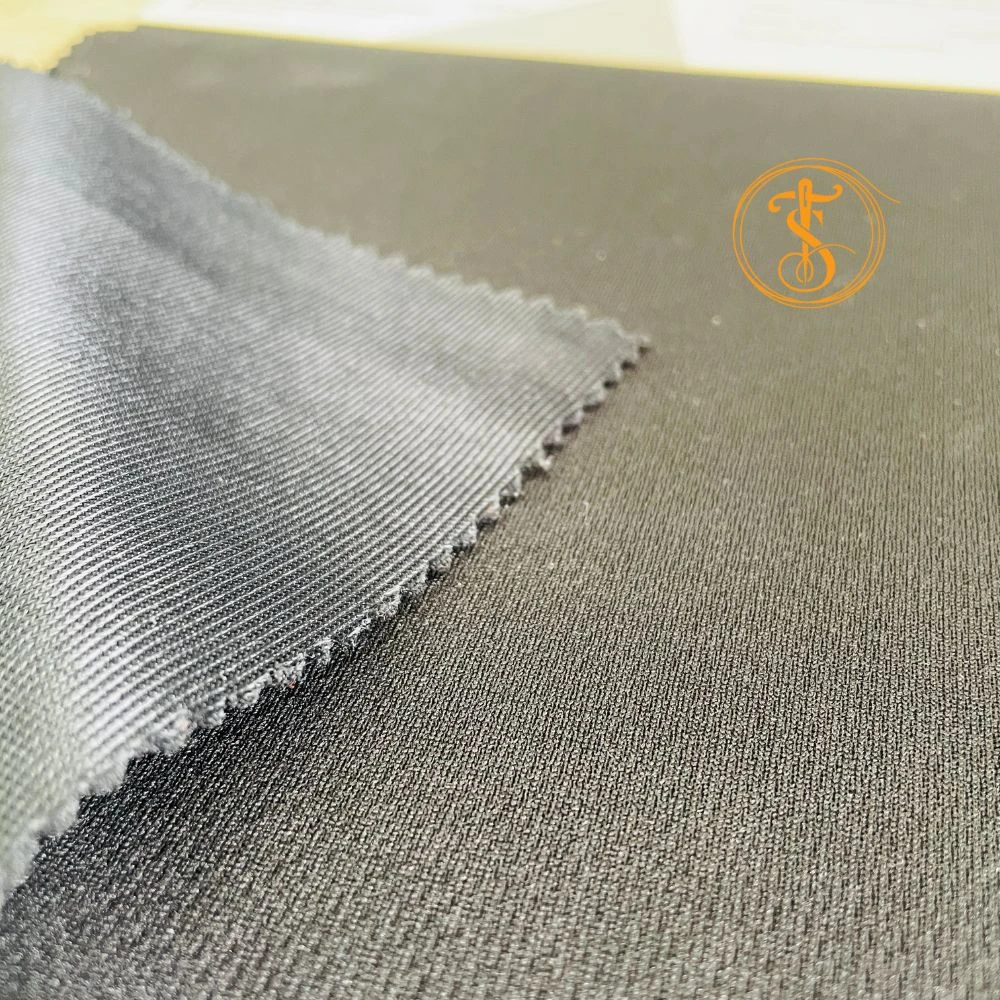

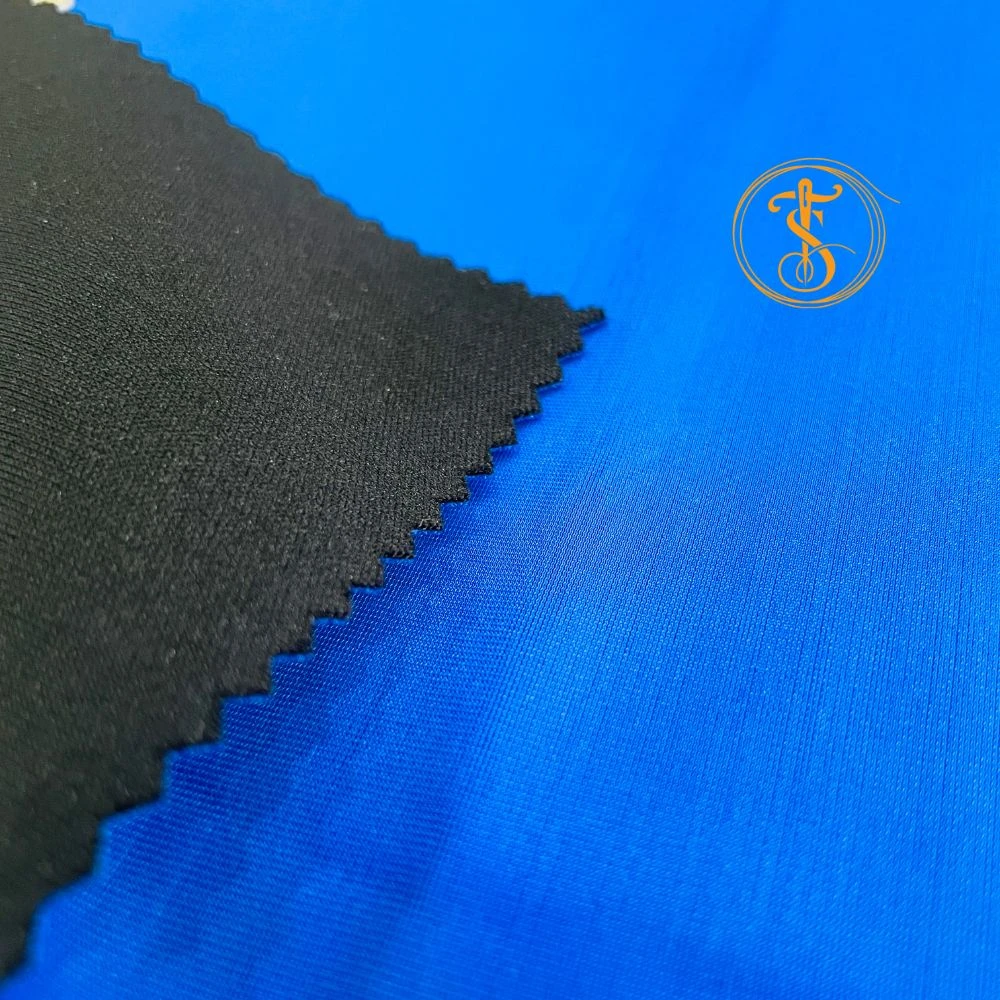

Bonded fabric is a non-woven material. Many fibers join to produce this bonded fabric. Blending is the process in which one textile gets manufactured with another one. The other textile yarn can be metal, plastic, or rubber-like yarn. There are bonding fiber webs that adhesively use in the industrial world.

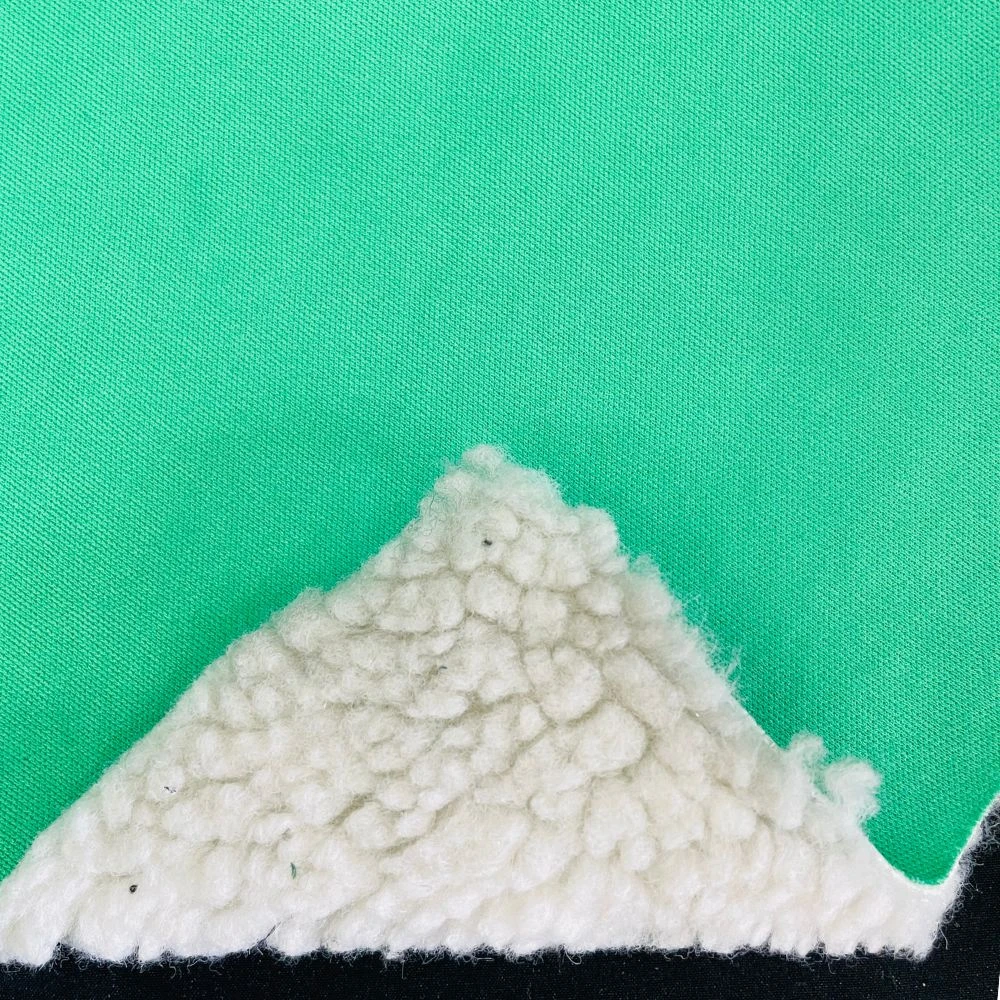

The bonded fabric or the adhesive material comes in powder form, resin, and even other different forms. Bonded fabric first came into light in England in 1952. Next year, a mesh-like material was introduced. Fabrics go through some developments as well. They contained bonded knit fabric, rubber, and wool-like situation.

What is Bonded Fabric made of?

Bonded fabrics are non-woven fabrics as we have mentioned before. They are made from fibers. As a result, bonded fabric tends to be weak, and they are prone to tearing. It requires direct bonding where two sheets get placed one in one position and heated. Meanwhile, polymeric resins flow between the sheets.

Also, there is indirect bonding. Here, one place gets placed directly at the top. Resin does not come close in contact. The most common resins are epoxy, phenolic, polyester, and polyimide. These resins strengthen the final product and increase the heat and chemical resistance.

Manufacturing of Bonded Fabric

Bonded fabric works well for general use. Creating this material is simple. There are two steps, the process of ironing, and pressing.

Step 1: Cut the expected fabric down in shape and arrange them on the top.

Step 2: Place the parchment paper between layers. These layers in the first place do not stick together in a shape.

Step 3: Ironing the fabric based on the directions. In this phase, layers will bond together and adds a final touch.

Step 4: Never use steam or never spray ‘starch’ material during the pressing situation.

Bonded Fabric Properties

|

Fabric Name |

Bonded Fabric |

|

Manufacturing Materials |

Fibers |

|

Fabric Durability |

Moderate |

|

Fabric Heat-Resistance Ability |

Heat-resistant |

|

Absorbent Ability |

Great absorbent due to the thick layer |

|

Non-Woven Nature |

Requires special technique |

|

Fabric Shine |

Shiny (Woven bonded fabrics) |

|

Fabric Stretchability |

Moderate. They can stretch and recover both. |

Characteristics of Bonded Fabric

Bonded fabric becomes acrylic adhesive. There is a latex adhesive for instance acrylate, vinyl chloride, vinyl acetate, and thermosetting resin.

The bonded fabric has a few features that have been of descriptive nature. They are as follows:

· End Use Performance

The bonded product has an end-user performance. It depends on the bond strength formed between layers. They are creative and applicable for water repellence, better resilience, and flame retardancy.

· Providing Stability

There are tricot knits and gauze that bond together to face fabrics in providing face fabric stability.

· Preventing Yarn slippage

There is a process that keeps the woven fabrics from yarn slippage and distortion.

· Stiff and Inelastic

Bonded fabrics are stiff and inelastic.

Bonded Fabric Benefits

Mostly, quilters enjoy bonded fabric projects. But this fabric makes the piecing a challenging situation. Durability is what quilters mostly emphasize. The benefits are as follows:

- Excellent for making bags and purses.

- Lightweight

- Adapts to any shape

- Great absorption capacity

- Breathable

- Long-lasting nature

- Waterproof ability

- Perfect for the wet clothes

- Use in Craft projects

- Difficult to tear

- No stretching or fraying

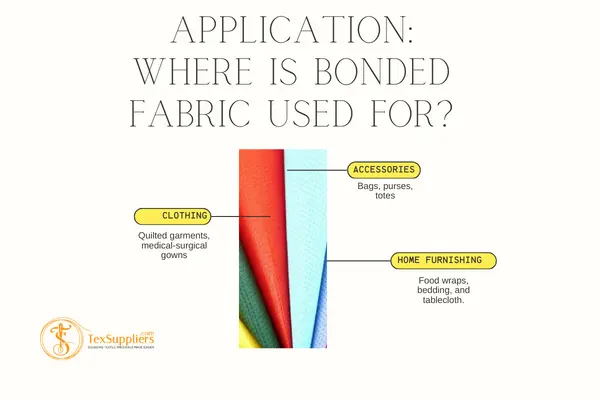

Application: Where is Bonded Fabric Used for?

The bonded fabric has several applications in the industrial sector. The areas are automotive parts, insulation materials, and packaging. The application areas depend on which material has better uses there.

Because the bonded fabric is non-woven and non-woven fabric gets used for the insulation purpose mostly. There is an automotive industry that extensively uses fuel lines. The key application areas are as follows:

· Clothing: Quilted garments, medical-surgical gowns

· Accessories: Bags, purses, totes

· Home Furnishing: Food wraps, bedding, and tablecloth.

Examples of Bonded Fabric

The bonded fabric has several examples starting from pre-pegs to baking sheets. The examples with descriptions are given in the following section:

· Pre pegs:

Here, the carbon fiber-like fabric impregnates with an epoxy resin. After that, it gets backed down with a fiberglass cloth

· Tapes:

Sheets are thin here. Still, it provides easy-to-handle support and weathering resistance.

· Textiles:

These are materials that are made with yarns and fabrics.

· Sheets:

Here, the sheets have a wide range of applications from cutting into shape to putting together in the structure for end use.

FAQs

- Does cotton count as a bonded fabric?

Yes, cotton is a bonded fabric. Bonded fabric applies to multi-layer of composite cloth. It gets used in protective apparel manufacturing.

· How to care for bonded fabric?

Bonded fabric washing requires dust removal using any soft brush. To wash the bonded fabric, you may need to use lukewarm water. The fabric also requires a clean cloth. In cleaning the stain, there should be a gentle cleaner.

Conclusion

A bonded fabric is a layered structure. Here, a face or fabric shell remains joined in backing a fabric including an adhesive. There is no such thing as a thickness that combined fabrics have. Artificial leather products can be an inclusive part of the bonded fabric example. In simplifying the garment construction, the lining fabric seems to be bonded. In the marketplace, you may find mostly polyester-made bonded fabric.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.