If we had to name only yarn name that has the finest quality and hardest manufacturing processes, we would be naming combed yarn. Combed yarn has the lowest production cost and the greatest demand in the textile industry. For daily needs, there is no other yarn with a perfect appearance except for the combed yarn.

Table Of Contents

What is a Combed Yarn?

Combed yarn refers to yarn created of straight and parallel fibers. The combed yarn is suitable for the weaving process due to its manufacturing process. The combed yarn gets stronger, smoother, and more compressed while being separated from the elongated fibers.

Compared to the carded yarn, this combed yarn is slightly costly as the weaving process takes a bit longer time.

What is Combed Yarn made of?

Combed yarn is the finest cotton-made yarn type. The entire procedure of making combed yarn with the presence of cotton makes the yarn smoother. As we have noted before, combed yarn undergoes the technique where fibers remain straight and parallel.

Products made of combed yarn are flawless for any type of sensitive skin. Here, the carding machine removes the short fibers from the elongated fibers and all the cotton impurities for combing progress.

Manufacturing Process of the Combed Yarn

In the combing processes, there are usually two useful procedures: Linear and Circular. Combed yarn goes through a method named grilling that makes the yarn perfect for the spinning procedure. After that, the yarn gets carded before use and then gets combed.

Combed Yarn Manufacturing: The Process Sequence

Flow Chart process: the Manufacturing of Combed Ya

In the combing process, a higher yarn count gets produced. The Combed Yarn is a fine material than any kind of carded or yarn of rotor. After carding, the combing gets done to ensure some extra steps for manufacturing.

|

Input |

process |

Output |

|

|

Fiber |

Lap |

||

|

Lap |

Carding machine |

Silver |

|

|

Silver |

Pre comb drawing |

||

|

Silver |

Lap former |

Lap |

|

|

Lap |

Combing |

Silver |

|

|

Silver |

Post comb drawing |

Silver |

|

|

Silver |

Simplex |

Roving |

|

|

Roving |

Ring frame |

Combed yarn |

|

|

|

Winding |

|

|

|

|

Reeling |

|

|

|

|

Bundling |

|

|

|

|

Bailing |

|

|

Description of the Manufacturing Process

The following are the fiber basics of the processing of the combed yarn in a spinning mill. These are:

- Blow Room: This room opens the fiber bale and lap that are going to produce for carding process. This tends to be the first stage of the spinning process

- Carding: Carding is nothing but the heart of the spinning process. Better carding facilitates better spinning production.

- Combing: This process introduces finer yarns in the spinning process. Here, the process removes short and staple fibers, fine kitty, naps, etc.

- Draw Frame: A machine that carries out drafting and doubling.

- Roving Frame: It produces roving which is a lesser count of fiber. A small twist applies to keep fiber altogether with the help of a roving frame. Here, the roving gets wound to a suitable package for the spinning machine’s feeding.

- Ring Frame: The final stage of yarn production is the Ring Frame. It drafts the roving for desired yarn counts. Also, the twisting and drafting require the count of yarn and strength. Twisted yarn wound helps a storage facility.

- Cone Winding: Produced yarns get winded in the cone form in the winding process.

- Reeling: A hank of yarn is produced from the cone. The hank forms the 10 pounds of the weighted bundle.

- Bailing: Here, the final bale of 400 pounds weight gets formed.

Properties of Combed Yarn

|

Yarn Name |

Combed Yarn |

|

Manufacturing Materials |

Cotton |

|

Yarn Durability |

High |

|

Resistance to High Temperature |

Yes |

|

Water-Absorbent Ability |

Less |

|

Yarn Strength |

Stronger |

|

Yarn Shine |

More lustrous |

|

Mostly Used In |

Clothing Production, Making linen fabric, t-shirts, knitting, weaving. |

|

Resistance to Pilling |

Better results |

|

Yarn Hairiness |

Low |

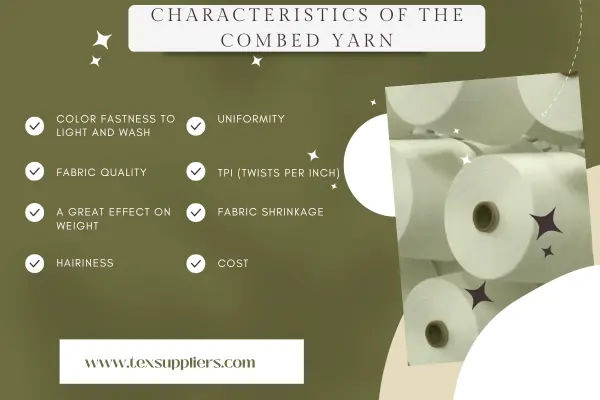

Characteristics of the Combed Yarn

Combed yarn, compared to carded yarn has multiple unique characteristics. These are:

- Color Fastness to Light and Wash

Any type of finished knit fabric made of combed yarn has no such significant changes due to the color’s fastness to light and wash.

- Fabric Quality

The different features of the combed yarn influence making the finest fabric quality of combed yarn.

- A Great effect on Weight

The combed yarn has the most effective feature on the GSM (Gram Per Square meter). Combed yarn compared to any type of carded yarn produces higher GSM using the same count and type of yarn.

- Uniformity

The Combed Yarn is more uniform in nature.

- TPI (Twists Per Inch)

The TPI of the combed yarn is lower.

- Fabric Shrinkage

Any fabric made of combed yarn is low in nature.

- Hairiness

Combed yarn is less hairy and tends to be gentle against the skin.

- Cost

Combed yarn making is expensive.

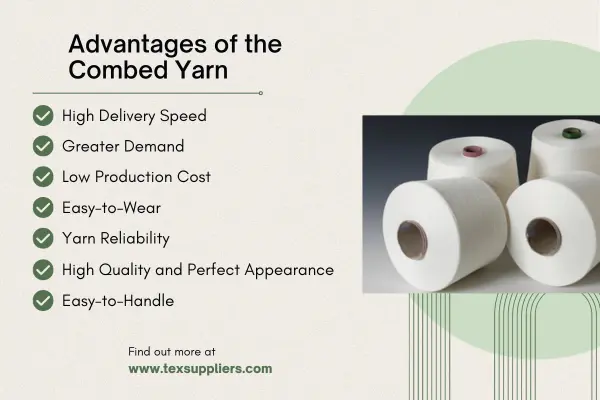

Advantages of the Combed Yarn

Combed yarn exceeds in the advantageous position with diversified ranges. They are:

- High Delivery Speed

Combed yarns, manufactured extensively, end up having a high delivery speed.

- Greater Demand

Combed yarns have never failed to attract demand. Also, the availability is in the higher amount too.

- Low Production Cost

The manufacturing is complex, yet the production cost is comparatively low in nature. As a result, combed yarn fulfills the demand with top-notch service.

- Easy-to-Wear

Combed yarn is easy to wear and smooth in nature.

- Yarn Reliability

The combed yarn reliability is appealing.

- High Quality and Perfect Appearance

Combed yarn comes with a lustrous appearance ensuring high quality and good shape ability.

- Easy-to-Handle

Combed yarn tends to be easy to handle and produces better quality.

Applications of the Combed Yarn

The Combed yarn is there to make T-shirts most of the time. Whatever product you make with the combed yarn, the product feels comfortable and less fuzzy. This yarn is perfect for making linen fabric. Most of the application of this combed yarn goes to the knitted garments. Whatever the garment type is, the outcome is soft and durable, thanks to the combed yarn’s powerful manufacturing process.

Conclusion

The material made by combed yarn tends to be supple as it undergoes multiple processes. Such heavy processes also make the fabric strong, as well as soft, compared to carded or another yarn type. The combed yarn has overpriced no doubt about that, yet the buying fabric is all worth it when we get them in a furnished way. Against any skin, combed yarn tends to have the best material due to its refined texture and daily wearability.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.