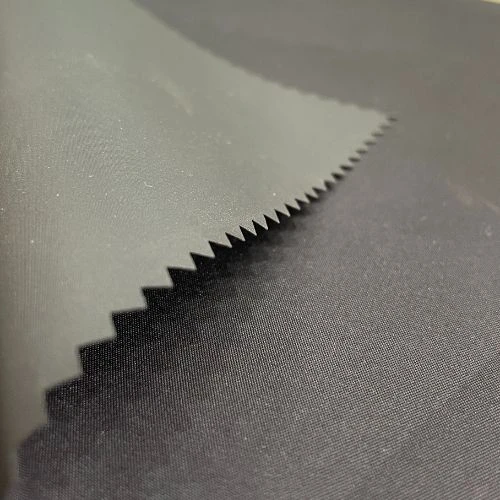

Let’s get this straight—300T Pongee fabric isn’t just some textile jargon. It’s a lightweight, finely woven polyester fabric known for smooth texture, slight sheen, and versatility. The “300T” stands for 300 threads per square inch, which gives it a tight weave and enhanced durability.

|

Parameter |

Details |

|

Also Known As |

300T Polyester Pongee, 300T Lining Pongee, 300T Taffeta Pongee |

|

Manufacturing Process |

Woven, Plain Weave → Piece Dyeing → Functional Coating (PU/PA/WR) |

|

Appearance |

Smooth, slightly glossy surface with a soft, sleek hand feel |

|

GSM Range |

60 – 90 GSM |

|

Composition Range |

100% Polyester (occasionally blended with ≤5% Nylon) |

|

Construction Range (Density) |

300 threads per square inch (typically 50D × 50D or 75D × 75D) |

|

Functionality Options |

PU (Polyurethane), TPU, AC (Anti-static), W/R (Water Repellent), PVC, PV |

|

Possible Yarn Count |

50D × 50D, 75D × 75D |

|

Full Width Options |

57/58", 59/60", 71/73" |

|

Fabric Breathability |

Moderate (coating may reduce airflow slightly) |

|

Stretchability |

Very Low (non-stretch unless spandex added, which is rare) |

|

Prone to Pilling/Bubbling |

Low risk if properly finished; PU coating helps resist bubbling |

|

Country of First Production |

Japan, Early 1980s |

|

Biggest Exporter (Recent Data) |

China (Over 450 million meters/year exported globally) |

|

Recommended Washing Temperature |

30°C – 40°C (cold to warm wash, no bleach) |

|

Finishing Uses to Increase Functionality |

PU Coating (waterproof), PA Coating (softness), AC (anti-static), Down-proof coating, UV-resistant finishes |

|

Colorfastness Rating |

4–5 (Excellent) according to ISO 105 standards |

|

Shrinkage Rate |

≤2% (dimensional stability when properly treated) |

|

Eco-Friendly Variants |

Available in recycled polyester (rPET) options |

|

Applications |

Jacket linings, windbreakers, umbrellas, tents, sleeping bags, backpacks, outdoor covers, sportswear shells |

|

Common Coating Weight (PU) |

600mm to 1000mm water pressure resistance rating |

|

Abrasion Resistance |

High (Martindale Test: ≥20,000 rubs for coated versions) |

|

UV Resistance |

Moderate to High (with appropriate coating) |

|

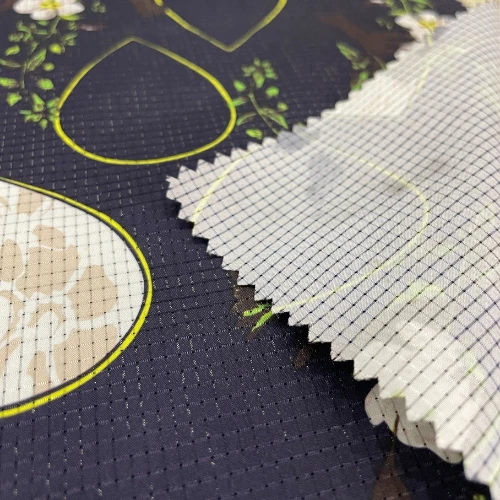

Printable Surface |

Yes – compatible with dye sublimation, heat transfer, and screen printing |

|

Flame Retardant Availability |

Optional – available upon chemical treatment |

|

Biodegradability |

No (unless made from biodegradable polyester blends or recycled fibers) |

|

Common MOQ for Export Orders |

1000–3000 meters per color/design |

|

Storage Notes |

Store in a dry area, avoid prolonged UV exposure to prevent coating decay |

This fabric isn’t just soft; it’s smart. It repels water, resists wrinkles, and stays looking fresh longer than your Monday morning face.

Table Of Contents

How is 300T Pongee Fabric Made?

Thread Count Explained (Why 300T Matters)

The “T” in 300T is short for thread count. In 300T Pongee, 300 threads are woven per square inch of fabric—more than enough to ensure strength without bulking up. That high thread count makes it denser and smoother than lower-T Pongees like 190T or 210T Pongee Fabric.

A tighter weave = better performance. It’s science.

Manufacturing Process of Pongee

Pongee is usually made from 100% polyester using fine filament yarns. The weave is plain—warp and weft intersect at right angles. It’s then dyed, often piece-dyed for uniform coloration, and finished with coatings like PU or PA for extra functions (water resistance, anyone?).

Technical Specs of 300T Pongee Fabric

Let’s talk numbers—because details matter.

GSM Range

300T Pongee typically ranges between 60 to 90 GSM. That’s light but not flimsy. Just right for linings, outer shells, and even camping gear.

Composition Breakdown

Most variants are 100% polyester, but some blends with nylon exist too. Polyester brings strength, wrinkle resistance, and affordability to the table.

Width and Yarn Count

- Full Width: Usually 57/58” or 59/60”

- Possible Yarn Counts: 50D × 50D, sometimes 75D × 75D depending on application

What Makes 300T Pongee Special?

Appearance and Feel

Silky. Subtle sheen. Smooth like a cat’s purr. That’s how 300T Pongee feels. It doesn’t scream luxury, but it whispers comfort.

Coating & Functional Finishes

300T Pongee is often enhanced with coatings such as:

- PU (Polyurethane) – Adds water resistance

- PA (Polyacrylate) – Improves softness and colorfastness

- W/R (Water Repellent) – Great for outdoor use

- AC (Anti-static Coating) – Keeps the cling at bay

Some even get PVC or TPU coatings for heavy-duty applications.

Water Resistance, Breathability & Durability

With PU or WR coatings, it handles light to moderate rain like a pro.

Breathability is decent but not exceptional—it’s no cotton.

Durability? You bet. It resists tears, creases, and even some UV damage.

Common Applications of 300T Pongee Fabric

Outerwear and Jackets

Used as shell fabric in windbreakers and raincoats. Not bulky, but strong enough to handle a hike through brambles.

Linings and Umbrellas

Ever opened an umbrella and felt that silky inside? That’s often 300T Pongee. Same goes for jacket linings—soft, strong, and slick.

Tents and Sleeping Bags

With coating, it becomes water-resistant and windproof—perfect for lightweight tents and sleeping bag linings.

Backpackers love it. And so do their backs.

Pros and Cons of 300T Pongee Fabric

|

Pros |

Cons |

|

Lightweight yet strong |

Not highly breathable without vents |

|

Water and wind-resistant (with PU) |

May need coating for weatherproof use |

|

Smooth, premium appearance |

Can feel synthetic if uncoated |

|

Affordable and widely available |

Not biodegradable (it’s polyester) |

|

Easy to dye, print, and coat |

Can melt under high heat |

Final Thoughts

300T Pongee fabric is like the Swiss Army knife of textiles—versatile, practical, and surprisingly elegant. It does the job whether you’re sewing jackets or pitching tents. The 300 thread count gives it just the right mix of smoothness and structure. Throw in some coatings, and you’ve got a material that fights the elements without fighting your wallet.

For fabric engineers, designers, or curious DIYers, it’s a solid pick.

FAQs About 300T Pongee Fabric

1. Is 300T Pongee waterproof?

Not by default. But with PU or W/R coatings, it becomes water-resistant enough for jackets and tents.

2. What does 300T mean in fabric?

It refers to 300 threads per square inch. Higher thread count means finer weave and smoother feel.

3. Can 300T Pongee be used for upholstery?

Not ideal. It’s too lightweight and may not withstand the abrasion that upholstery demands.

4. Is it safe to iron 300T Pongee?

Use low heat. Polyester melts at high temperatures. Steam carefully—or skip the iron.

5. How does 300T compare to 190T or 210T?

300T is smoother, tighter, and more durable. It looks and feels more refined than lower thread count versions.

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.