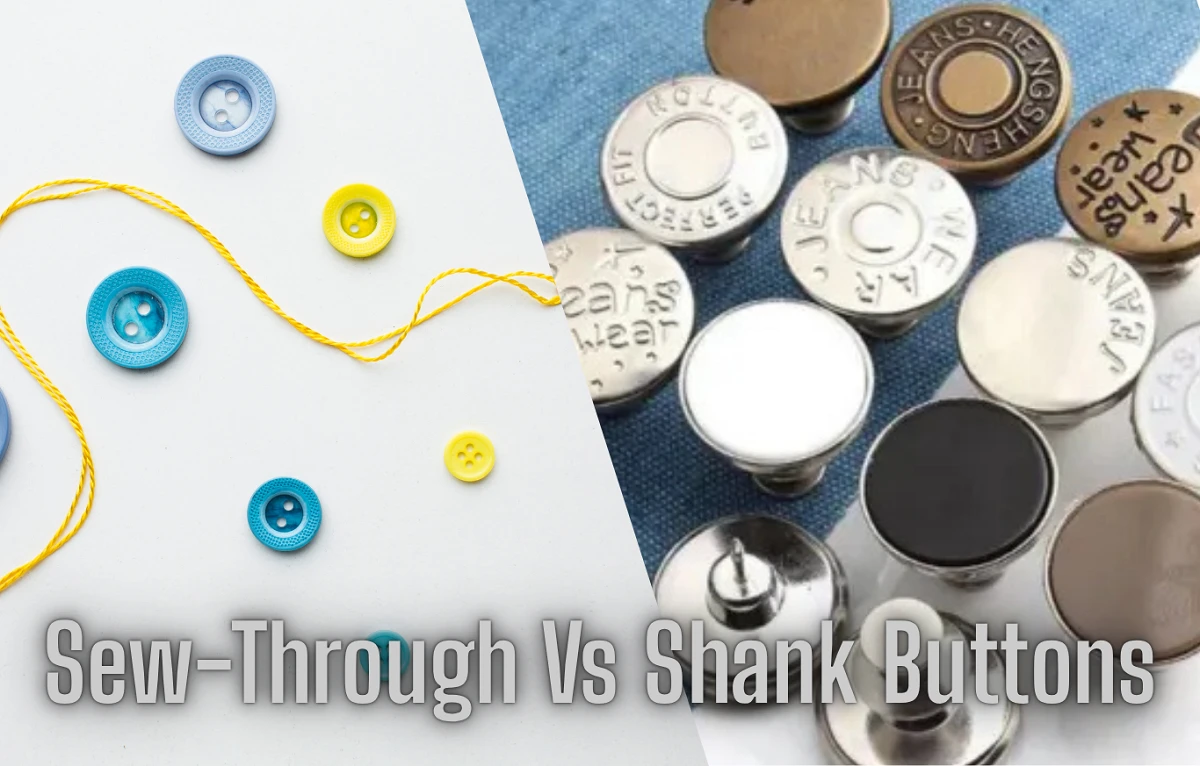

Buttons might seem small, but they play a big role in how garments look, feel, and perform. Whether it’s your shirt, coat, or blazer, the type of button you use matters. Two of the most common types are sew-through buttons and shank buttons. Sounds simple, right? But the difference between them goes beyond just holes and hooks.

Table Of Contents

What Are Sew-Through Buttons?

A sew-through button is a type of button that has two or four holes passing completely through its surface, allowing it to be sewn directly onto the fabric using thread. It has no separate shank or loop at the back — instead, the thread holds the button flat against the garment.

Imagine the classic shirt button you’ve seen since childhood — flat, round, and punctured with small holes. That’s a sew-through button. It’s the simplest and most widely used button design in the textile industry.

These buttons have two or four holes drilled through the top surface, allowing the needle and thread to pass through directly to the fabric.

A 2023 survey by the Global Button Market Review found that around 65% of buttons used in apparel production are sew-through types, mainly due to their simplicity, affordability, and adaptability across materials like plastic, polyester, and wood.

How Sew-Through Buttons Are Made

Manufacturers often mold these buttons from polyester or resin under high pressure and temperature. After molding, the holes are drilled precisely, ensuring uniformity and smooth edges.

Modern factories use CNC machines to create perfectly aligned holes with tolerance levels under 0.1 mm, ensuring consistency across mass production.

Common Materials and Uses

Sew-through buttons appear everywhere from cotton shirts and baby rompers to denim jackets and pillow covers. They’re available in endless variations:

- 2-hole buttons for lightweight fabrics.

- 4-hole buttons for thicker or structured garments.

- Decorative sew-through buttons in wood, shell, or horn for aesthetic appeal.

If you’ve ever buttoned a shirt in a hurry and fumbled? Yep, that’s likely a sew-through button you were wrestling with.

What Are Shank Buttons?

Now picture a button with no visible holes on top — just a clean, elegant face. Flip it, and you’ll find a small loop or shank at the back where the thread passes through. That’s the shank button, the favorite of luxury tailors and fashion houses.

A 2025 fashion manufacturing report noted that over 80% of designer coats and blazers use shank buttons, mainly due to their polished look and professional finish.

Construction and Design

The shank (a small metal, plastic, or fabric loop) acts as a bridge between the button and the garment. This gap helps thicker fabrics sit naturally without distortion or pulling.

Shank buttons are made from metal, enamel, or covered fabric, often featuring embossed logos or decorative finishes. That’s why they’re common in military uniforms, jackets, and couture dresses.

Why Shank Buttons Are Popular in High-End Garments

Here’s a simple truth: Shank buttons just look expensive. The absence of visible stitching gives garments a sleeker, tailored appearance. Plus, that little gap created by the shank prevents thread tension — meaning the fabric drapes beautifully.

Fun fact: the average lifespan of a metal shank button is twice as long as a plastic sew-through one, especially under dry-cleaning conditions.

Key Differences Between Sew-Through and Shank Buttons

|

Feature |

Sew-Through Button |

Shank Button |

|

Attachment |

Sewn through visible holes |

Sewn through hidden loop (shank) |

|

Appearance |

Flat, visible stitching |

Clean, elevated face |

|

Best for |

Shirts, casual wear |

Coats, blazers, dresses |

|

Fabric Compatibility |

Light to medium weight |

Medium to heavy fabrics |

|

Ease of Sewing |

Easier to attach |

Slightly complex |

|

Durability |

Moderate |

High |

|

Cost |

Low |

Medium to high |

Appearance and Structure

Sew-through buttons sit flush on fabric, while shank buttons rise slightly due to their built-in loop. This elevation creates visual depth — perfect for garments that need a premium finish.

Function and Attachment Method

In a sew-through button, the thread secures the button flat to the cloth. In contrast, shank buttons suspend slightly, allowing thick fabric layers to fasten without wrinkling.

Durability and Comfort

Sew-through buttons might break faster under tension since the thread is exposed. Shank buttons, protected by the loop design, often last 1.5x longer in wear tests performed by garment technologists in 2022.

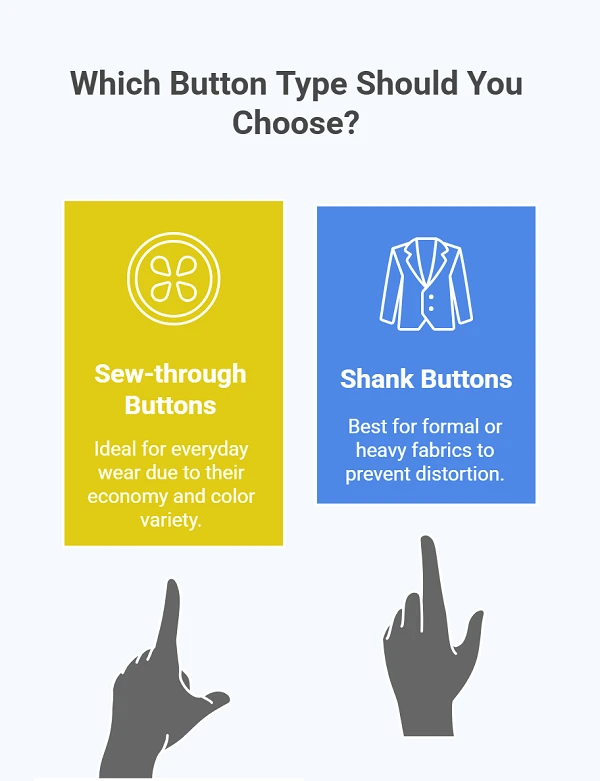

Which Button Type Should You Choose?

For Everyday Wear

If your project involves shirts, babywear, or casual tops, sew-through buttons are your best bet. They’re economical, easy to replace, and available in massive color options.

For Formal or Heavy Fabrics

Go for shank buttons if you’re sewing coats, blazers, or dresses made from wool, velvet, or denim. They prevent fabric distortion and keep the garment structure intact.

The Textile Technologist’s Take

As someone who has worked with countless garment prototypes, I can confidently say — there’s no “better” button overall. It depends entirely on the fabric weight, garment purpose, and visual appeal.

Conclusion

The difference between sew-through and shank buttons lies not just in how they attach, but in how they influence a garment’s function and style. Sew-through buttons bring simplicity and everyday usability. Shank buttons add elegance and structure. Both deserve a place in your wardrobe and your sewing kit — because, in fashion, even the tiniest details make the biggest statements.

FAQs

1. Which button type is more durable?

Shank buttons tend to last longer since their thread is protected by the loop structure.

2. Can I use sew-through buttons on a blazer?

Yes, but they might flatten the lapel area. Shank buttons provide a cleaner finish for structured fabrics.

3. Are sew-through buttons easier to sew?

Definitely. They’re quicker to attach, especially for beginners or machine sewing.

4. What materials are shank buttons made from?

They can be metal, resin, fabric-covered, or even glass, depending on the garment’s style.

5. Which button type looks more formal?

Shank buttons. Their hidden stitching and raised profile add a refined, high-end touch.

.webp)

Comments - 00

Leave A Reply

Thanks for choosing to leave a comment.